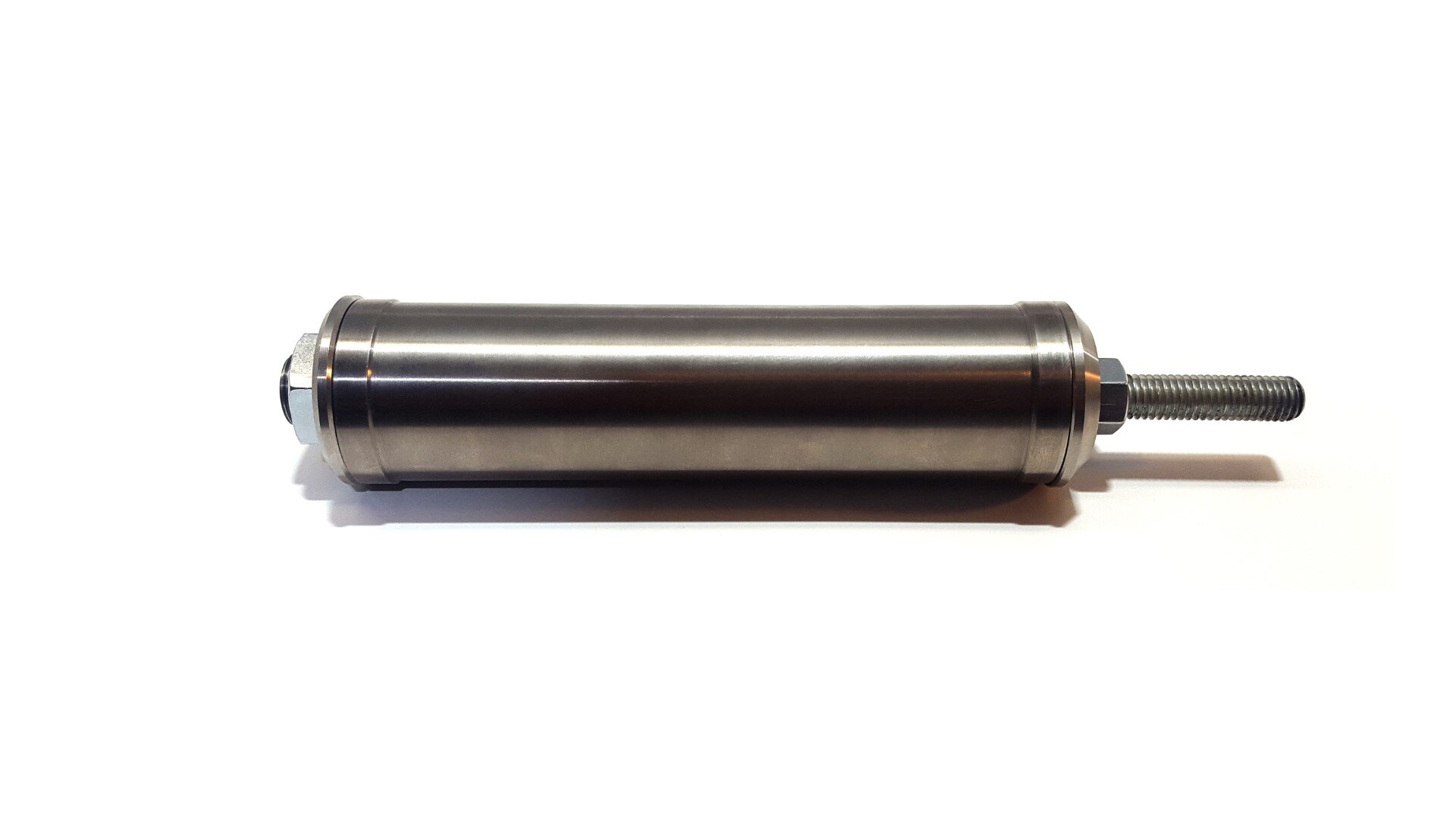

Frame builders take note that in the TUBING + MATERIALS section of the website we have a new heat sink for 44mm head tubes.

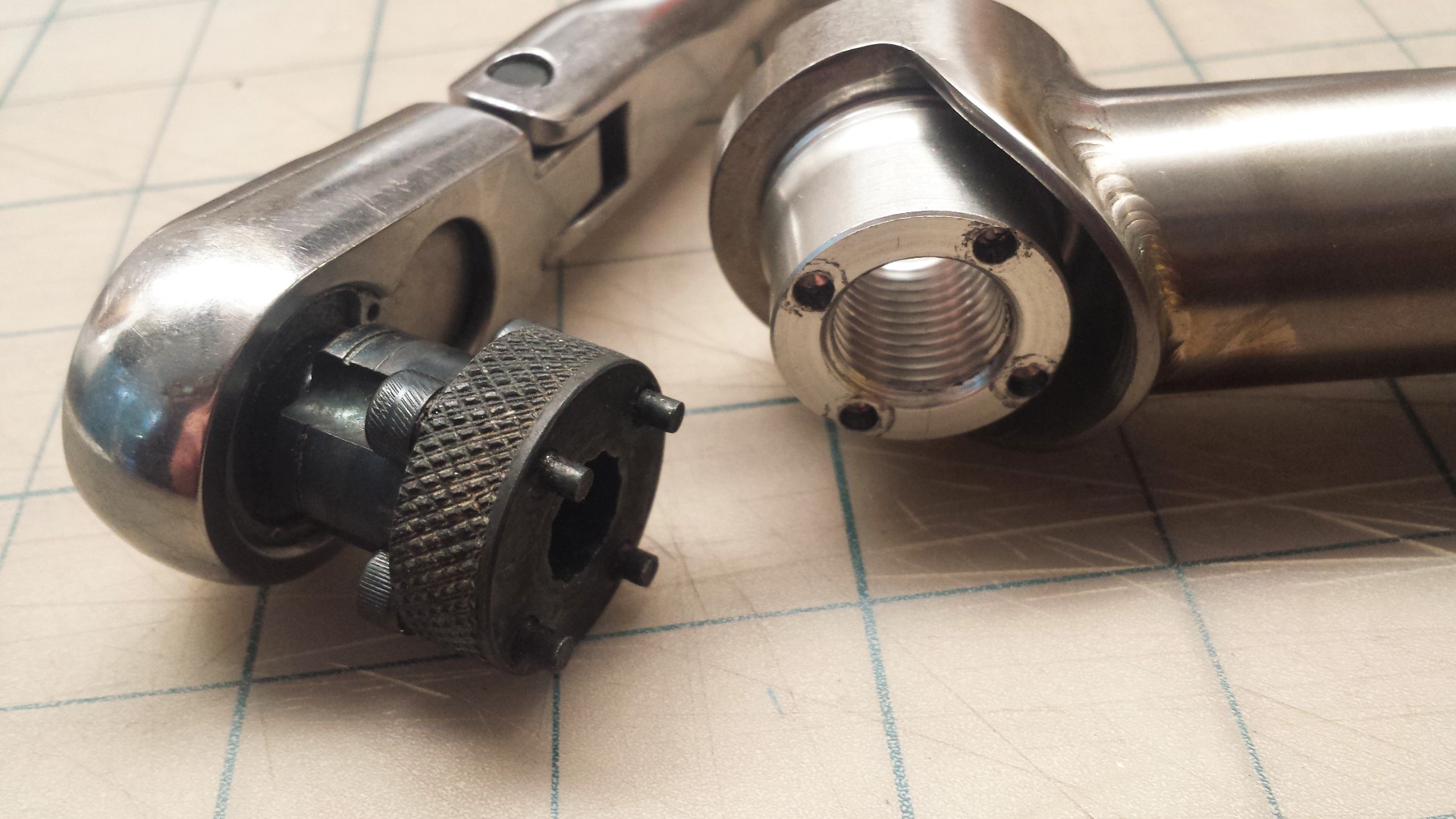

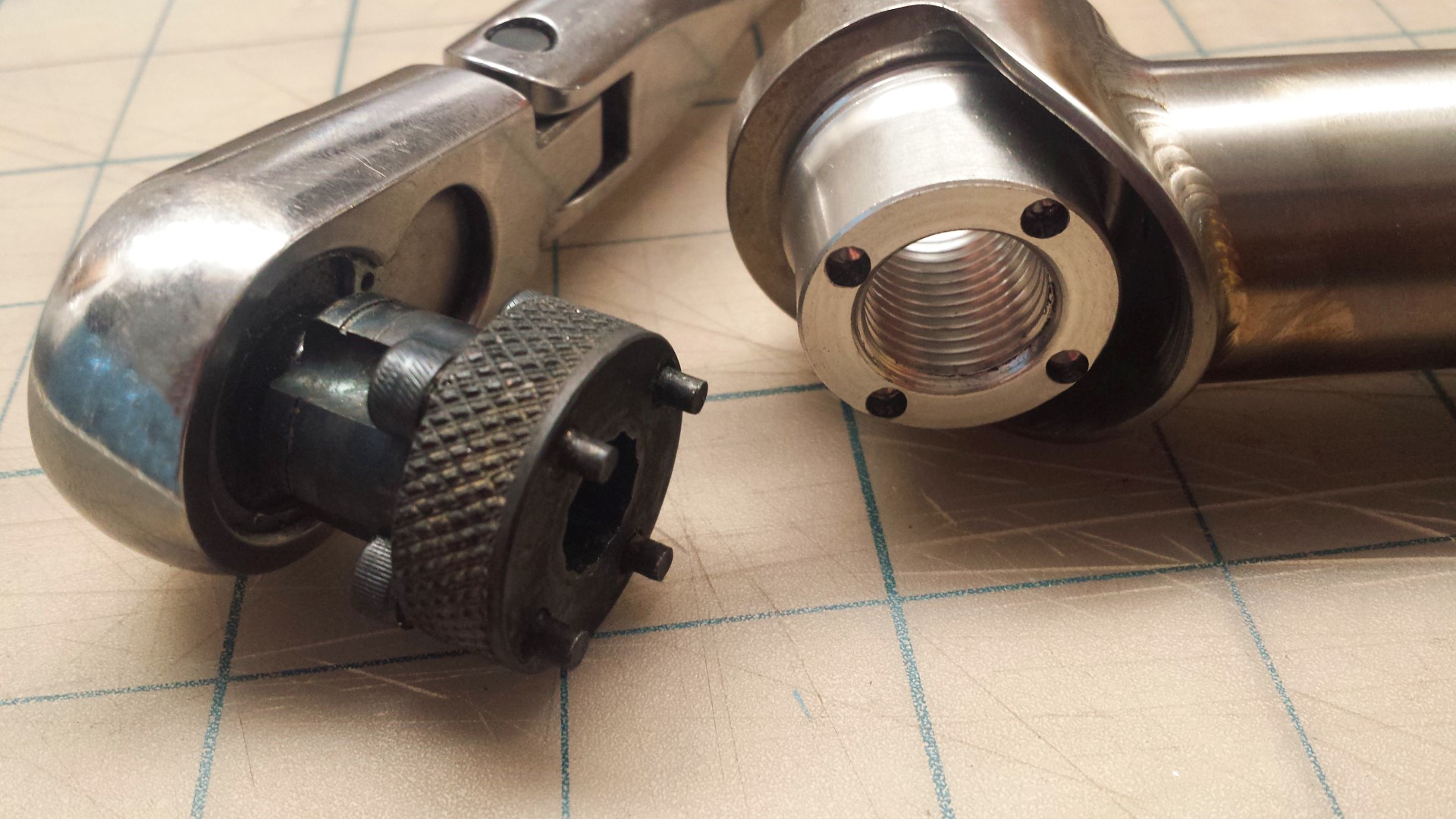

Designed specifically for welding up longer sizes of the TiCycletubes thin walled 44mm head tubes, these brass heat sinks are made entirely in house and make quick work of putting together the front end on large frames.

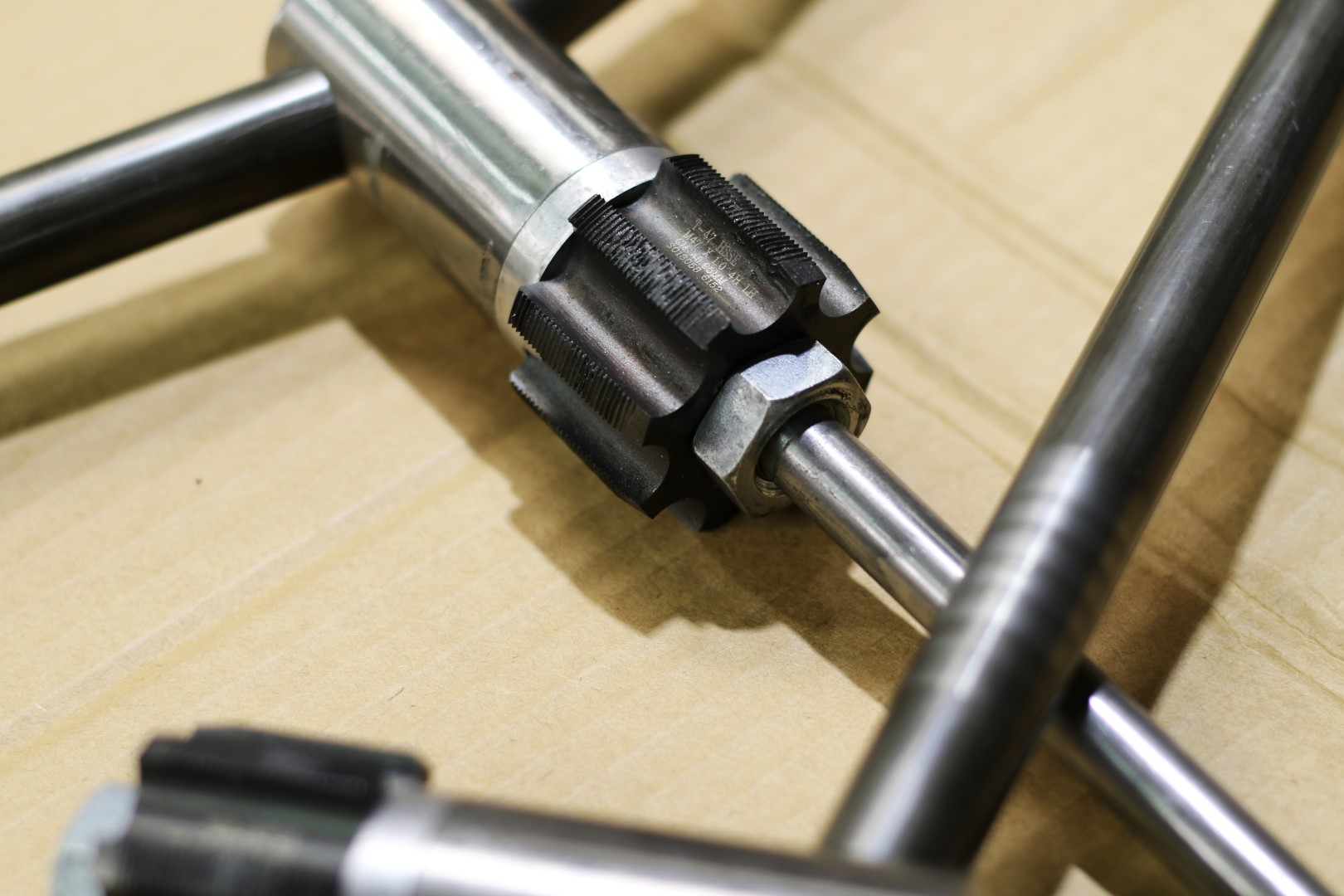

This tool is compatible with 100-250mm length tubes and with a fitment for standard purge fittings on one end and one nut and cone cap on the other the heat sink has a flip flop design that can quickly move from top to bottom of the head tube, speeding production.

Oh, and since it is compatible with 44mm - 48mm ID tubes, it works with 100mm T47 bottom bracket shells too! Available now, in stock and ready to ship.